- ArmaFlex Ultima is a flexible insulation with low smoke emissions, improving fire safety and energy efficiency.

- The product is based on patented ArmaPrene technology and is FM-approved and IMO compliant.

- It provides reliable thermal and condensation control, minimising corrosion under insulation (CUI) risks.

- ArmaFlex Ultima can operate from -50 °C to +110 °C, saving 140 times more energy than required for its production.

Fire Safety and Environmental Compliance

ArmaFlex Ultima and its variants meet stringent fire safety standards and environmental requirements.

- ArmaFlex Ultima achieves Euroclass B/BL-s1,d0 classification, indicating low smoke density and flame resistance.

- The product is free from brominated flame retardants, PVC, and antimony, making it suitable for green building certifications like LEED and BREEAM.

- ArmaFlex Ultima C offers enhanced fire performance for larger applications. Its grey covering improves mechanical protection and condensation control.

Technical Specifications and Performance

The technical data for ArmaFlex Ultima highlights its superior performance characteristics.

- The thermal conductivity is declared at λd ≤ 0.040 W/(m·K) at 0 °C and 0.045 W/(m·K) at 40 °C.

- It has a water vapour diffusion resistance factor (μ) of ≥ 7,000, ensuring effective moisture control.

- The product is self-extinguishing, does not drip, and has very low smoke density, enhancing safety during fires.

- It is designed for a service temperature range of -50 °C to +110 °C and has specific guidelines for cryogenic applications.

Product Range and Applications

Armacell's product catalogue includes a variety of insulation solutions for different sectors.

- The catalogue features products for commercial buildings, residential buildings, industrial applications, and transportation.

- Key products include ArmaFlex Ultima, ArmaFlex Ultima C, and various adhesives and accessories tailored for specific insulation needs.

- The insulation solutions apply to HVAC, refrigeration, and process equipment, ensuring energy savings and condensation prevention.

ArmaFix Ultima Pipe Support Overview

ArmaFix Ultima is a specialised pipe support designed for B-s1, d0 ArmaFlex systems. It emphasises fire safety and low smoke emissions.

- Provides superior fire performance and reduced smoke density.

- Compatible with the ArmaFlex Ultima product range.

- Prevents thermal bridges, reducing energy losses and CO₂ emissions.

- First flexible closed-cell insulation with Euroclass B(L)-s1,d0 rating.

- Service temperature range: -50°C to 110°C.

- Self-extinguishing, does not drip or spread flames.

Technical Data for ArmaFix Ultima

The technical specifications detail the materials, applications, and performance characteristics of ArmaFix Ultima.

- Made from PET-foam bearing segments and ArmaFlex Ultima elastomeric foam.

- Available in dark blue colour.

- Applications include refrigeration and air-conditioning installations.

- Density: 95 - 105 kg/m³ for pipe bearing segments.

- Fire performance is rated Euroclass E; the entire system with ArmaFlex Ultima tubes is rated B(L)-s1, d0.

- Shelf life of 3 years when stored properly.

AF/ArmaFlex Evo Product Features

AF/ArmaFlex Evo represents the latest generation of elastomeric insulation, focusing on fire safety and energy efficiency.

- Offers improved fire-retardant properties and low smoke generation.

- Infused with Microban antimicrobial protection to prevent mould and mildew.

- Engineered wall thicknesses for reliable condensation control.

- An extended warranty of up to 10 years is available for certified installations.

- Service temperature range: -50°C to 110°C.

- Declared thermal conductivity: λd ≤ 0.033 W/(m·K) at 0°C.

Technical Data for AF/ArmaFlex Evo

The technical specifications provide detailed information on the material properties and performance of AF/ArmaFlex Evo.

- Made from flexible elastomeric foam based on synthetic rubber.

- Self-adhesive coating with pressure-sensitive adhesive.

- Applications include insulation for pipes, air ducts, and vessels in HVAC and refrigeration.

- Fire performance rated B(L)-s2, d0 for tubes and B-s2, d0 for sheets.

- Water vapour diffusion resistance factor: μ ≥ 10,000 for tubes.

- Antimicrobial behaviour was confirmed, and no fungal growth was observed.

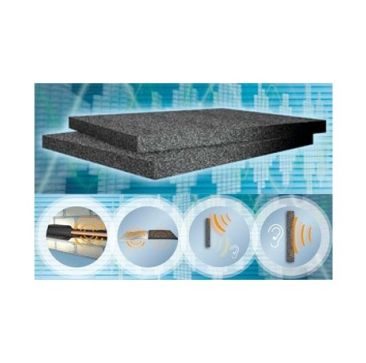

AF/ArmaFlex General Product Information

AF/ArmaFlex is a highly flexible insulation material designed for various applications in HVAC and refrigeration.

- Provides reliable condensation control and prevents corrosion under insulation (CUI).

- High flexibility and ease of installation enhance user experience.

- Offers a 10-year system warranty for professional installations.

- Available in various thicknesses and forms, including tubes and sheets.

- An Environmental Product Declaration (EPD) is available, indicating sustainability credentials.

Tube Specifications and Variants

The text provides detailed specifications for various types of tubes, including standard and self-seal options.

- Standard tubes are available in black with a length of 2.0m.

- Variants include AF-5 and AF-6 with different inner diameters and insulation thicknesses.

- Thickness tolerance varies by type: AF-1, AF-2: ±1.0 mm; AF-3, AF-4: ±1.5 mm; AF-5: ±2.5 mm; AF-6: ±3.0 mm.

- Length tolerance for all tubes is ±1.5%.

Self-Seal Tube Options

The text outlines the self-seal tube options available, emphasising their insulation properties.

- Self-seal tubes are available in various sizes, including AF-1, AF-2, AF-3, and AF-4.

- Insulation thickness ranges from 7.5 mm to 22.5 mm depending on the variant.

- Lengths vary from 4 m to 234 m based on the specific item.

- Most items utilise a tangential cut, with some using a radial cut surface.